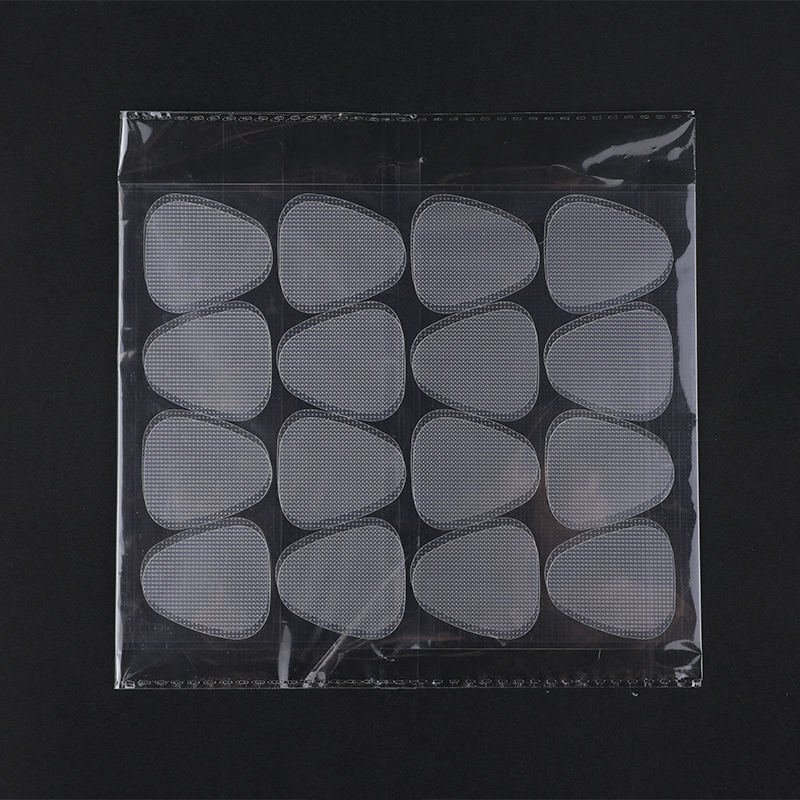

The Central Role of Adhesion and Breathability

When examining the qualities that define a wrinkle-reducing patch, adhesion and breathability emerge as two of the vital attributes. Adhesion ensures that the patch remains in direct contact with the skin surface, maintaining its position throughout the recommended wear period. Breathability, on the other hand, guarantees comfort, reduces the risk of irritation, and allows natural moisture and oxygen exchange to take place. An Anti Wrinkle Patch Factory must therefore place these two properties at the core of its production philosophy. Without strong adhesion, the patch may shift or detach, undermining the delivery of active ingredients. Without breathability, the skin may feel suffocated, potentially causing redness, breakouts, or general user dissatisfaction. Achieving both in harmony is an intricate challenge that combines material science, process precision, and stringent quality control.

Precision Engineering in Layered Design

Creating a layered patch structure that can deliver active ingredients while balancing adhesion and breathability. Manufacturers often employ a multi-layered approach, in which an adhesive layer is paired with a breathable membrane and an active delivery surface. The adhesive layer ensures skin contact, while the breathable component prevents trapped heat and sweat. Advanced lamination techniques ensure these layers integrate seamlessly, avoiding weak points where adhesion could fail or breathability could be restricted. Micro-perforation technologies further refine this design, allowing air to pass through the patch without diminishing its adhesive strength or disrupting the delivery of beneficial compounds.

Manufacturing Processes to Secure Performance

During production, techniques such as precision coating and adhesive distribution play a key role. Factories must guarantee that adhesives are applied evenly across the patch surface to prevent zones of excessive stickiness or insufficient grip. At the same time, automated machinery calibrates the thickness of each layer to maintain the delicate balance between durability and comfort. Sophisticated inspection systems, often using imaging technology, monitor patches during assembly to ensure uniformity and detect flaws. These measures reduce variability, ensuring that each product leaving the factory floor performs consistently when applied to the skin.

Rigorous Testing for Adhesion and Breathability

No patch reaches the market without passing through rigorous testing protocols. Adhesion is assessed by simulating real-world conditions such as perspiration, natural oils, and repetitive facial expressions. Patches must remain attached without causing discomfort or leaving residue upon removal. Breathability, meanwhile, is evaluated by measuring moisture vapor transmission rates to ensure that the skin maintains its natural respiration. Such tests help confirm that the product not only adheres effectively but also supports long-term skin health. In many cases, dermatological trials are also conducted to validate safety and comfort for sensitive skin types.

Balancing User Experience with Effectiveness

The ultimate goal of any producer is to create a product that combines user experience. Adhesion that is too strong can make removal painful, while weak adhesion can render the patch ineffective. Excessive breathability may limit the delivery of active compounds, while insufficient airflow may irritate. By continuously fine-tuning adhesives, adjusting polymer blends, and improving structural designs, manufacturers manage to achieve a balance where patches are reliable, skin-friendly, and effective.